Published on the 30th January 2026 by ANSTO Staff

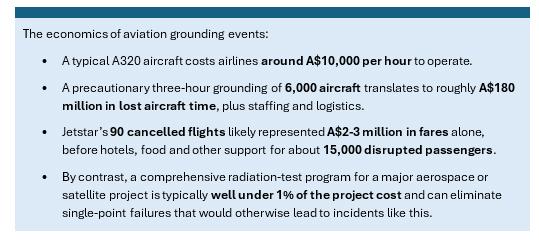

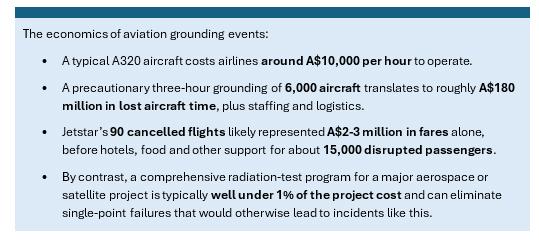

For industry and government, space radiation can be mapped as a balance sheet problem. Some simple estimates illustrate the scale.

When aircraft are grounded, airlines don't simply lose their operating costs - they lose the profit they would have earned. Understanding this distinction matters for anyone making investment decisions about radiation-hardness testing.

A typical A 320 generates revenue of around A$15000-18000 per flight-hour through ticket sales, ancillary fees, and cargo. Operating costs run to approximately A$10,000-11,000 per hour – covering fuel, crew, maintenance reserves and aircraft lease or depreciation. The difference, roughly A$5000-7000 per hour, represents the airline’s contribution margin: the profit that vanishes when the aircraft sits idle.

If one estimates, conservatively, that each of the approximately 6,000 affected aircraft spent three hours on the ground while software was updated, that is 18,000 aircraft-hours of lost productive time. This amounts to A$90-126 million in forgone profit (contribution margin alone), plus fixed costs that airlines cannot avoid – grew wages, airport slot fees, lease payments, regardless of whether the aircraft flies. The total economic impact likely exceeds A$150 million globally, without counting missed connections, crew repositioning or lost revenue.

In Australia, Jetstar’s 90 cancelled flights affected more than 15,000 passengers with a conservative economic impact of A$3 million in fares tied up in cancellations, re-bookings and refunds, plus accommodation, food vouchers, extra staff hours and knock-on delays. But the foregone profit on those flights – revenue that simply evaporated – adds millions more to the true cost.

And these are the costs from a single software vulnerability, caught quickly, during a weekend when airlines had some scheduling flexibility. The economic damage from a failed satellite, a defence platform taken offline, or a prolonged space-weather event affecting navigation and communications would be vastly larger.

By comparison, the cost of building radiation-hardness testing into the design and qualification of electronics is typically well under one per cent of a major project’s budget.

For a satellite mission costing A$300 million, a comprehensive radiation test campaign might run in the low single-digit millions. For safety-critical avionics or automotive systems, the numbers are even less. Yet that spend can remove or substantially reduce single-point failure modes like the one Airbus faced.

Until recently, Australian companies developing space or aviation hardware often had to send components overseas for radiation testing, navigating export controls, long wait times and significant cost. That creates a natural barrier to small and medium enterprises, and it slows innovation.

ANSTO’s Centre for Accelerator Science changes that calculus. It provides a test capability for radiation-hardness assurance – a requirement that is increasingly written into defence, space and aviation procurement. It also supports the broader Australian space industry through NSQN, reducing dependence on foreign facilities and keeping high-value work—and skills—in Australia. It also allows Australian researchers and companies to prototype, iterate and debug designs quickly, rather than waiting months for a single overseas test slot.

Events like the A320 grounding underline that radiation is now a cross-sector risk. The same physics that can knock a satellite offline can also scramble data in an aircraft, a high-altitude drone, a quantum sensor platform or a future autonomous vehicle. Australia benefits when those systems are designed, tested and qualified against our own best understanding of space weather and atmospheric radiation.

Looking ahead

As Solar Cycle 25 peaks, it can be assumed that more episodes where space weather intrudes into everyday life— from spectacular aurorae to GPS glitches and, occasionally, grounded aircraft.

The Airbus A320 recall is therefore more than a headline about “solar storms grounding planes”. It’s a case study in why radiation-hardness testing needs to be built into the lifecycle of critical electronics—not bolted on after something goes wrong.

ANSTO’s Centre for Accelerator Science can already reproduce many of the environments that aircraft, satellites and advanced electronics will experience, and they are working with industry, defence and academia to turn that capability into safer, more resilient technology.

The Sun is not going to get any less active in the near term. The question for Australia is whether we choose to treat radiation as an unpredictable external shock—or as a design constraint we can measure, model and engineer around.

This is part 2 of a series prepared with the assistance of Dr Mitra Safavi Naeini. Read Part 1